In the world of AI-powered protein engineering, there's a universal truth: a model is only as good as the data it's trained on. The greatest challenge in developing any AI-driven tool, particularly for protein engineering, is the scarcity of reliable and abundant training data. This data encompasses everything from basic amino acid sequences and 3D structures to complex functional properties, such as stability, solubility, and expression levels.

Cracking the data code: how ACROBiosystems unlocked AI-enabled protein engineering

AI-powered protein engineering promises speed, precision and scalability - but only if you have the right data. For most teams, that’s the biggest barrier. For ACROBiosystems, it’s a decade-long advantage. Read this blog by Ruiyuan Zheng, Marketing Product Manager, ACROBiosystems, to learn more about how they solved it.

At ACROBiosystems, we've been quietly solving this data problem since 2010. Our core business of recombinant protein expression has generated a unique asset: a deep, well-characterised repository of protein data. Now, we're leveraging this asset to power the next generation of protein design.

In a function-driven protein engineering process, modifications are tested through extensive simulations and analysis. Traditional protein engineering relies on wet lab tests, which are heavily specialist-dependent, require high costs, and are limited in the number of tests. In contrast, AI-driven protein engineering conducts automatic environment simulations and saves all that cost.

Answering the expanding demand, the AcroAIx platform is out. It oversees the design-build-test-learn cycle by operating in a dry-wet closed-loop system, comprising mutation library forming, high-throughput screening, and ‘AI box’-directed optimising. Trained with in-house expression data, AcroAIx provides exceptionally high data quality and prediction accuracy. Its robustness, proven in multiple internal projects, empowers higher, faster, and stronger pharmaceutical manufacturing.

Proof in performance: stabilising IL-21

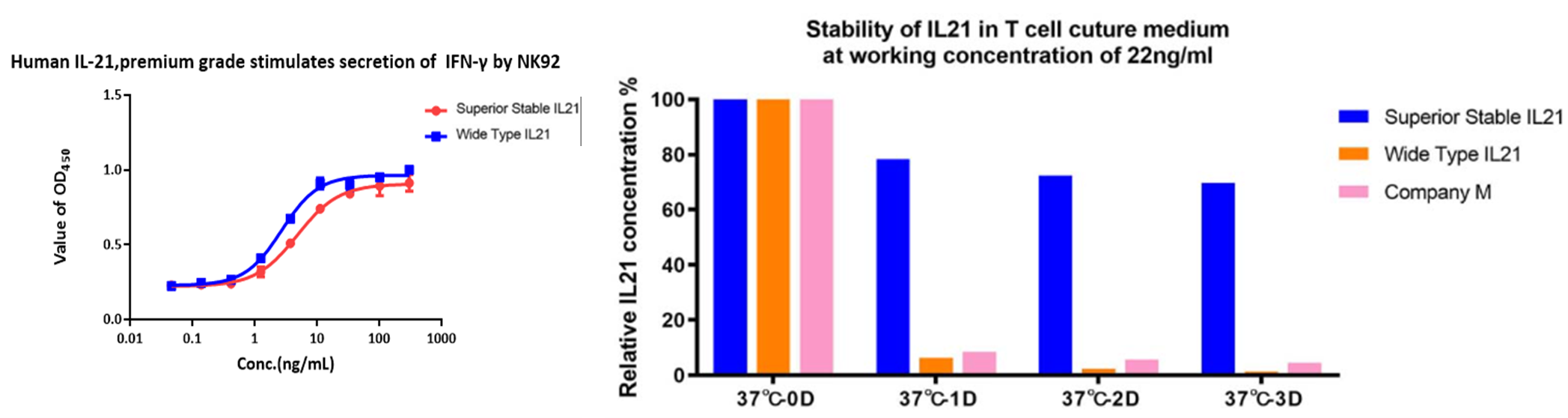

Take one commercialised example. IL-21 has multiple applications in the production of immunotherapeutic agents, promoting the differentiation of T helper cells and enhancing the cytotoxicity of CD8+ T cells. Relatively low stability of IL-21 limits its effectiveness in therapeutic applications. Substantial previous research has been conducted to modify its loop region and introduce additional disulfide bonds to address this issue. Building on previous attempts as valuable input, scientists at ACROBiosystems established a whole-sequence mutagenesis library, from which candidates were looped into a modification-experiment cycle to determine the best working model. This process continued until one candidate stood out as the ‘superior stable’ variant that tolerates cell culture temperatures continuously (Figure 1).

Figure 1. The AcroAIx-engineered superior IL-21 stimulates the secretion of IFN-g almost as well as the wild-type IL-21, while being much more thermostable.

This is just the beginning. The AcroAIx platform is now a core component of our mission to overcome the most challenging barriers in protein engineering. With every new project, it learns and improves, promising a future where designing high-performing proteins is faster, more reliable, and accessible than ever before.

Meet the ACROBiosystems team at bioProcessUK on 25-27 November in Newcastle to learn more.