EngBio Innovator Spotlight: Touchlight

UK companies are working across a diverse range of applications of engineering biology. Featured in the 'Power of Biology: The UK is engineering biology for global good' report, the following case study highlights Touchlight and gives additional insight into how this transformative technology can be used across healthcare, industry and agriculture.

Q: What does the company do?

Touchlight makes DNA using enzymes.

Q: How does the technology work?

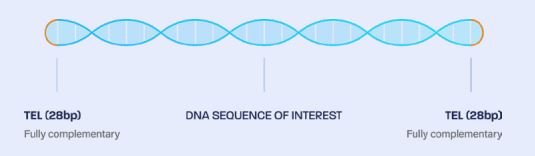

The company uses engineered enzymes to rapidly and accurately copy any given DNA sequence. Its resulting ‘doggybone DNA’ (dbDNA™) vectors – named for their shape – are closed-ended double-strands of DNA. These can be manufactured at commercial scale in just weeks compared to months using plasmid DNA production in E.coli. The dbDNA is stable, reliably reproduces the desired DNA sequence, and doesn’t contain any unnecessary material as it is made outside of cells. This means it avoids some of the safety concerns surrounding plasmid DNA, such as antibiotic-resistant genes used for plasmid selection.

Q: What impact is the technology having?

The technology has many applications, from cell and gene therapy and nucleic acid vaccines in healthcare to generating battery power in the industry.

1. Revolutionising the rapid growth of genetic medicine.

Touchlight technology is relieving the bottleneck in DNA manufacturing by manufacturing DNA in a faster, simpler and more cost-effective way. This has opened up a panacea of opportunity in genetic medicine and the company is already working with many pharma and biotech companies.

2. Generating power from naturally occurring materials in the bio-battery.

Touchlight is working with the UK Ministry of Defence, the Defence Science and Technology Laboratory, the University of Utah and the US Department of Defense, on this first-of-its-kind project. The technology takes naturally occurring products such as lactate, breaks them down using enzymes, and as they break down, they release electrons. These electrons are then captured and used as power. The batteries that the military carry currently are made from a mix of chemicals which could explode if shot. The bio-battery is made out of DNA, enzymes, lactate and water so is significantly safer. The hydrogel that makes up the battery can be dried out and reconstituted with water – even seawater - giving an energy-dense battery that can be carried easily and reconstituted anywhere. Not only is the battery safer and easier to use than current technology, it’s also a greener solution to generating power as the materials used in it are natural and will degrade over time.

What is the future for the company?

The company continues to expand and will be opening the biggest capacity DNA manufacturing plant in the world in Q3 of 2022. Touchlight continues to look for new opportunities to partner with pharma and biotech companies that could benefit from using the technology.

.png)

.png)